Diy Ceramic Coating Manifold

This in turn will mean cooler intake temperatures and more power.

Diy ceramic coating manifold. Ceramic has high resistance and is very durable. Zybar heat dissipation technology increases horsepower torque by improved scavenging reduces radiant heat over 90 and reduces under hood temperatures. Drboost powerdork 11 20 13 10 58 a m. Just like the diy ceramic coating industry buyers should be aware of the products and installation companies doing the.

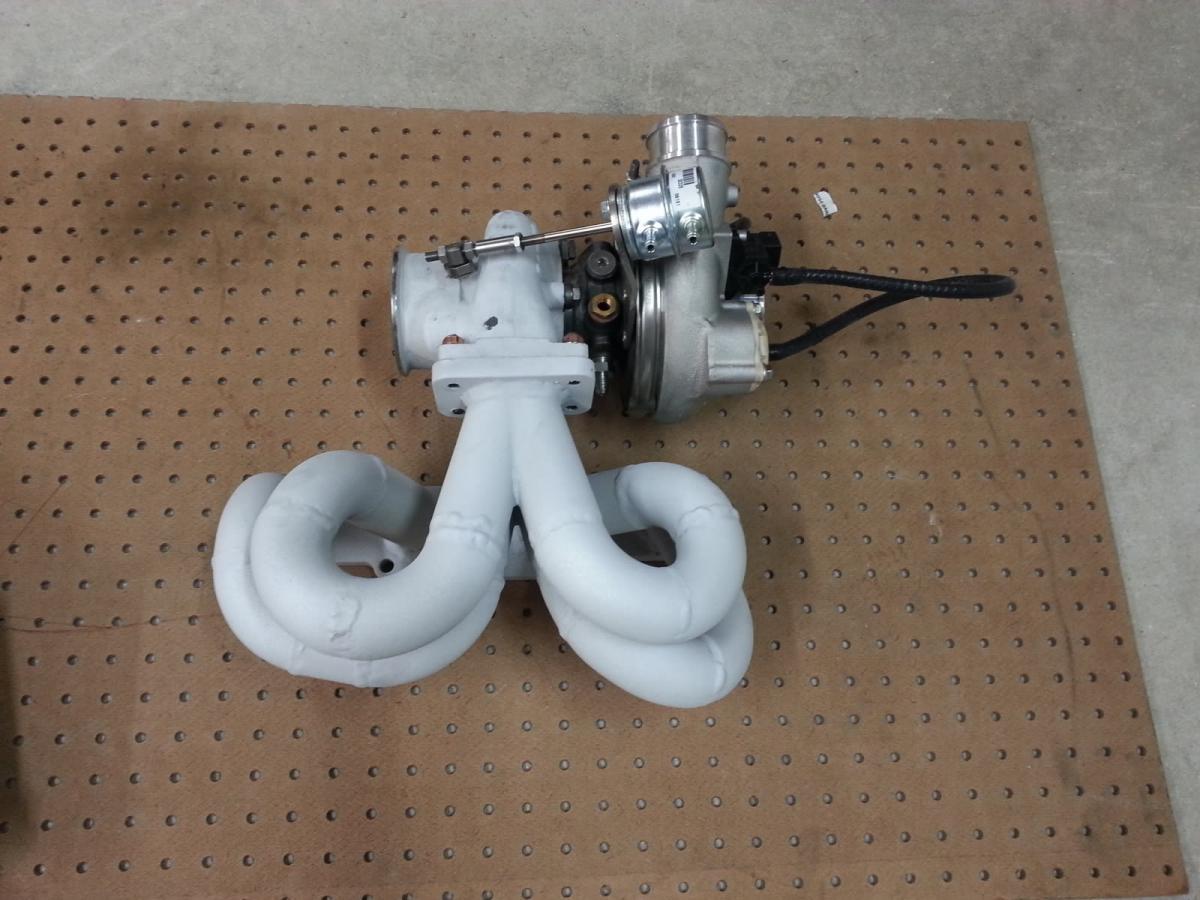

This video will show how a diyer sprayed vht ceramic coating to their turbo housing on their mazda. Most of them range from 1 000 to 2 500 based on the product how many applications and desired warranty. And because i want to improve the looks of the engine bay with their polished coatings. Diy ceramic coating turbo and manifold vht flameproof exhaust coating.

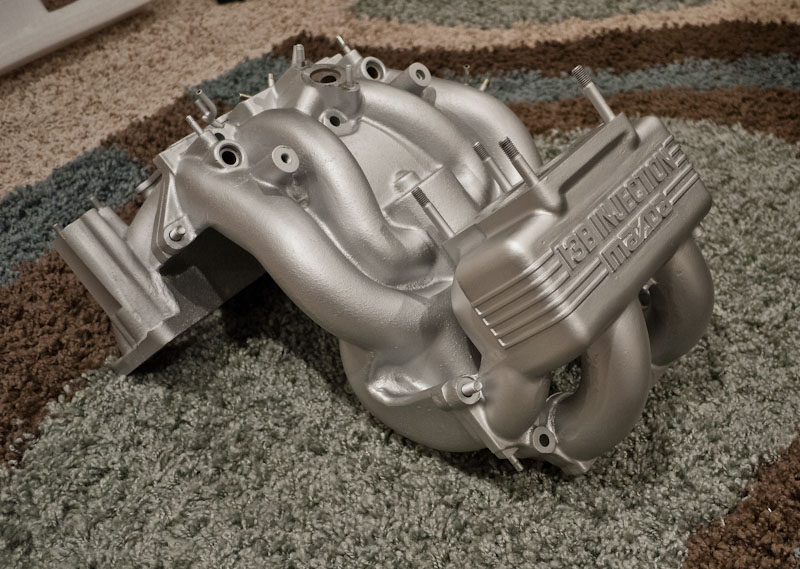

Our standard manifold and header paints are rated for up to 1 400 degrees and come in gray silver and black colors. If you thought the engine gets hot you should see the exhaust parts. Remember that there are estimates. Do it yourself patented high temperature coating for headers manifolds exhaust and turbos.

When compared to most high quality diy nano ceramic coatings the professional option is more costly. Has anyone ever ceramic coated headers or other part themselves. Also going to do the turbo manifold and related parts for the conversion of the 924 as well. This technique has been adapted by many motorsport competitors and is commonly used on any part that will experience high temperatures.

Diy ceramic coating headers. Use eastwood high temp exhaust coatings on your vehicle to provide protection in extreme conditions. The main item to remember is to follow the directions of each manufacturer as the will vary. Ceramic coating is fantastic as a heat insulator and will reduce the surface temperature within the exhaust by up to a third.