Disadvantages Of Ceramics Processing

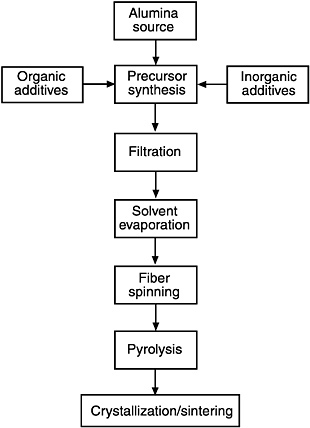

There are different production process methods are used in the ceramic production process.

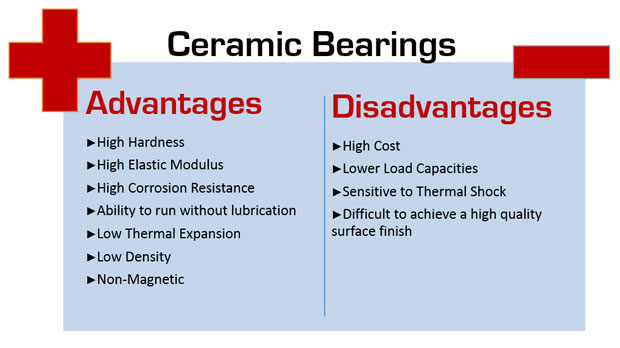

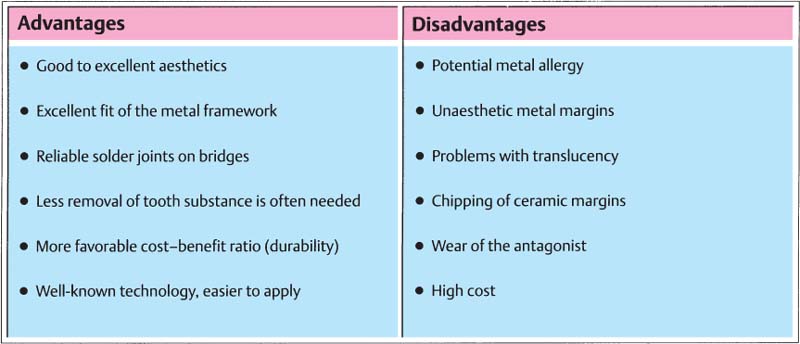

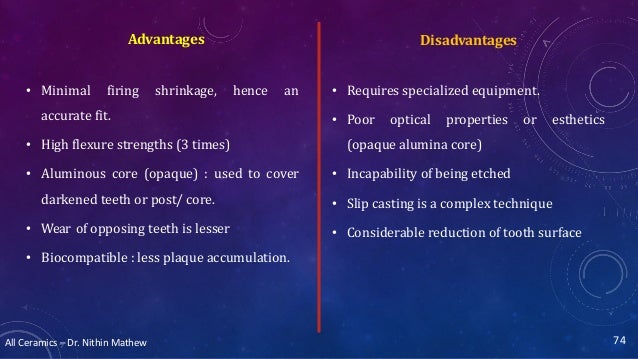

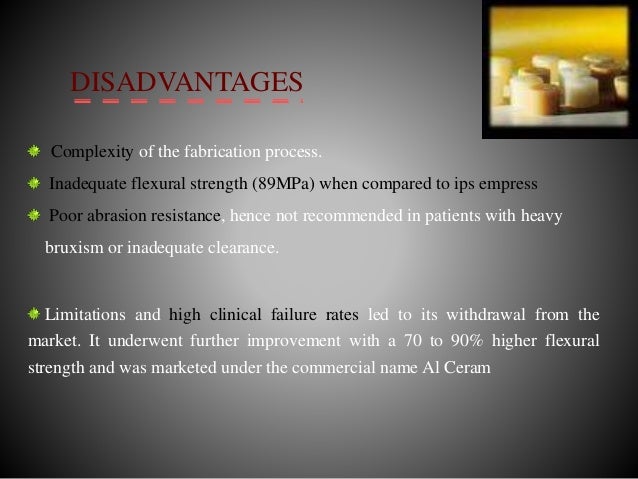

Disadvantages of ceramics processing. The advantages of ceramic over other materials are numerous and although there are some downsides to the use of this material as a whole it is a product which is is extremely compatible with maintaining a clean carefree and safe household and lifestyle. Ceramic decor items dishes and building materials add unique and personal touches to any home. To receive parts without admixtures it is required to have clean 100 powder. Can crack when hit with heavy items.

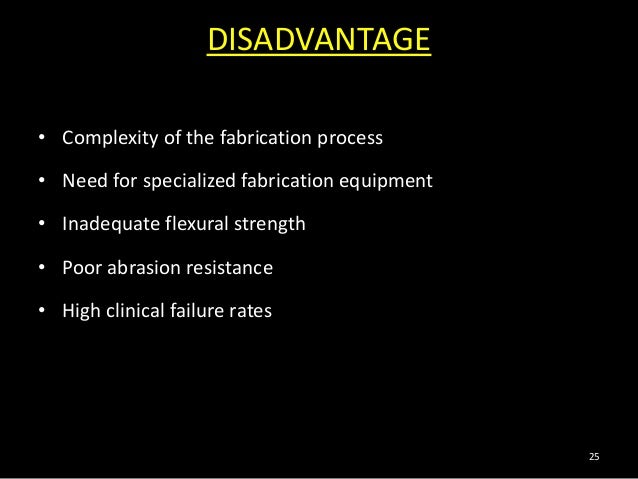

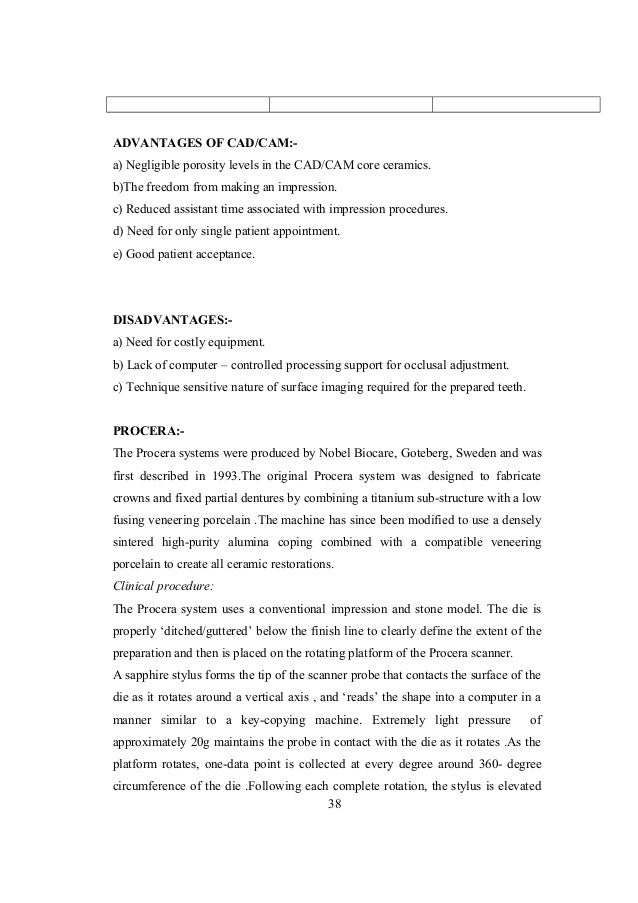

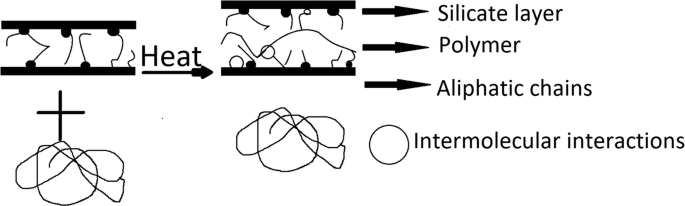

Complexity of production of big parts. All the above mentioned advantages of ceramic coating come at a high price. To have all the advantages of this coating user have to pay a high price as well. Mixing to obtain a more chemically and physically homogeneous material prior to forming the constituents of the ceramic powder are combined using the method of mixing or blunging.

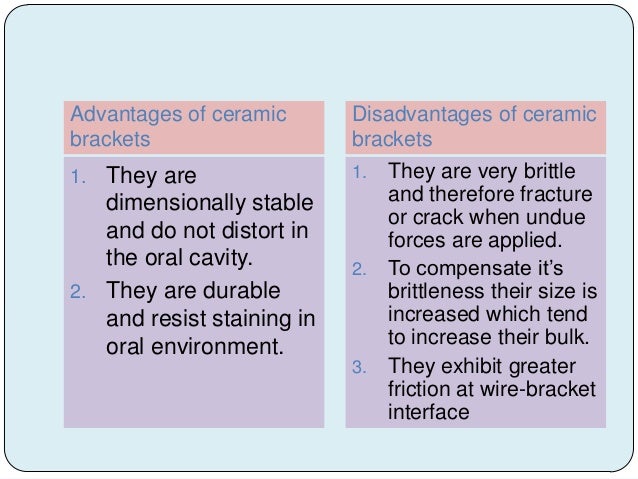

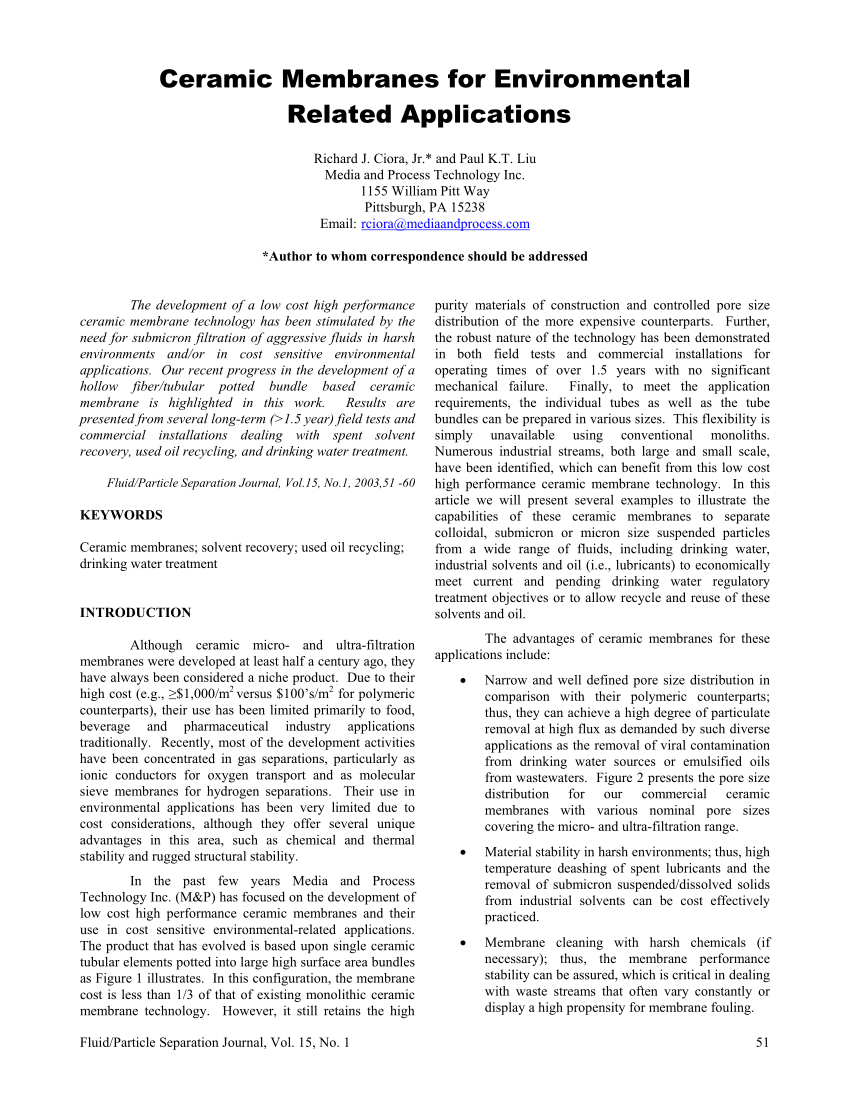

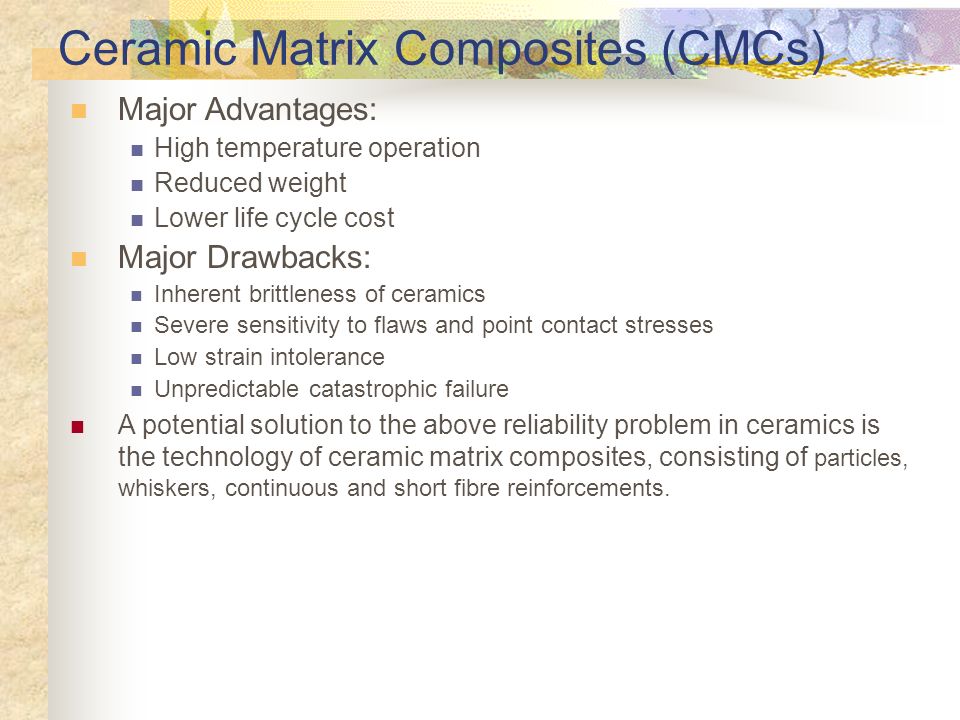

Ceramic processing the higher performance of ceramics is the result of strict contr ol of purity composition microstructure and processing. The market price of ceramic coating an average car is in the range of rs 25 000 to rs. Ceramic mold casting has advantages and disadvantages. Because of their inherent brittleness ceramics cannot be formed by rolling extrusion drawing etc their high melting temperatures also add restrictions on the use of casting techniques.

Takes time to be put in. In conclusion disadvantages of the sintering are not constantly active factors. High cost of raw materials. We will discuss all the production process methods used in the ceramic industry.

Dimensional tolerances difficult to control during processing. What are the advantages and disadvantages of ceramic. For using ceramic coating you still have to pay higher price than the traditional paints. Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes.

Disadvantages of ceramic coating. It is also important to add binders or plasticizers as well. The term ceramic forming describes the process of production of ceramic components from natural or synthetic raw materials. Ceramic coating takes time to be put in to our vehicles.

Harder than conventional structure metals. On the flip side of the cost however the process can eliminate the need for secondary processes that require machines to finish or refine the process.