Directed Energy Deposition Of Ceramics

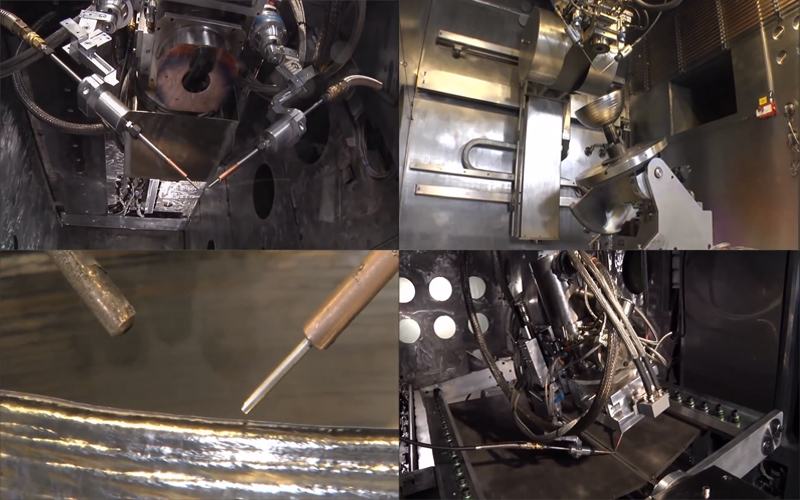

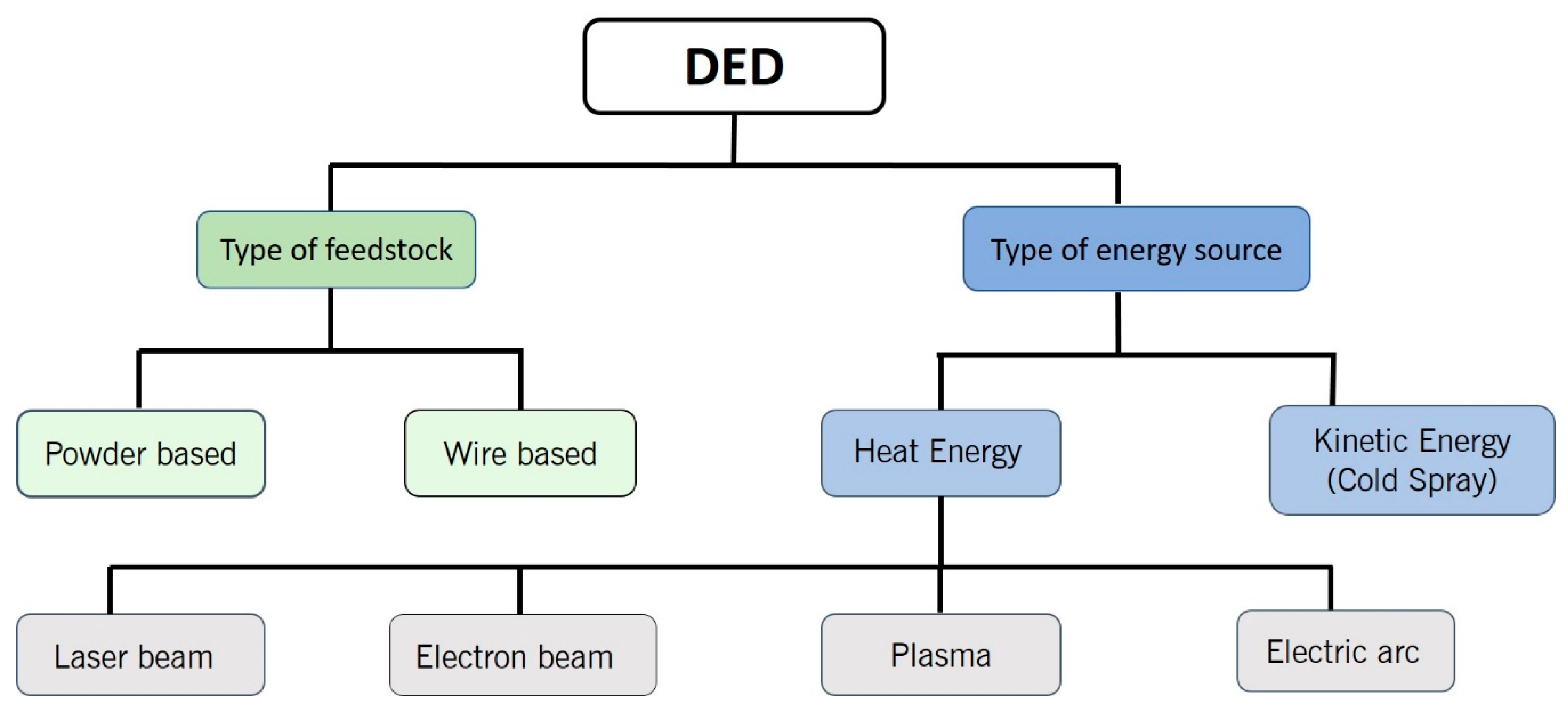

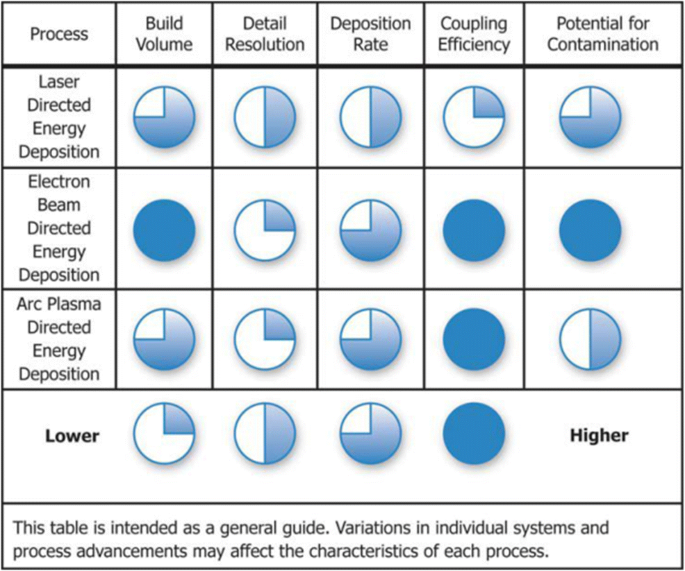

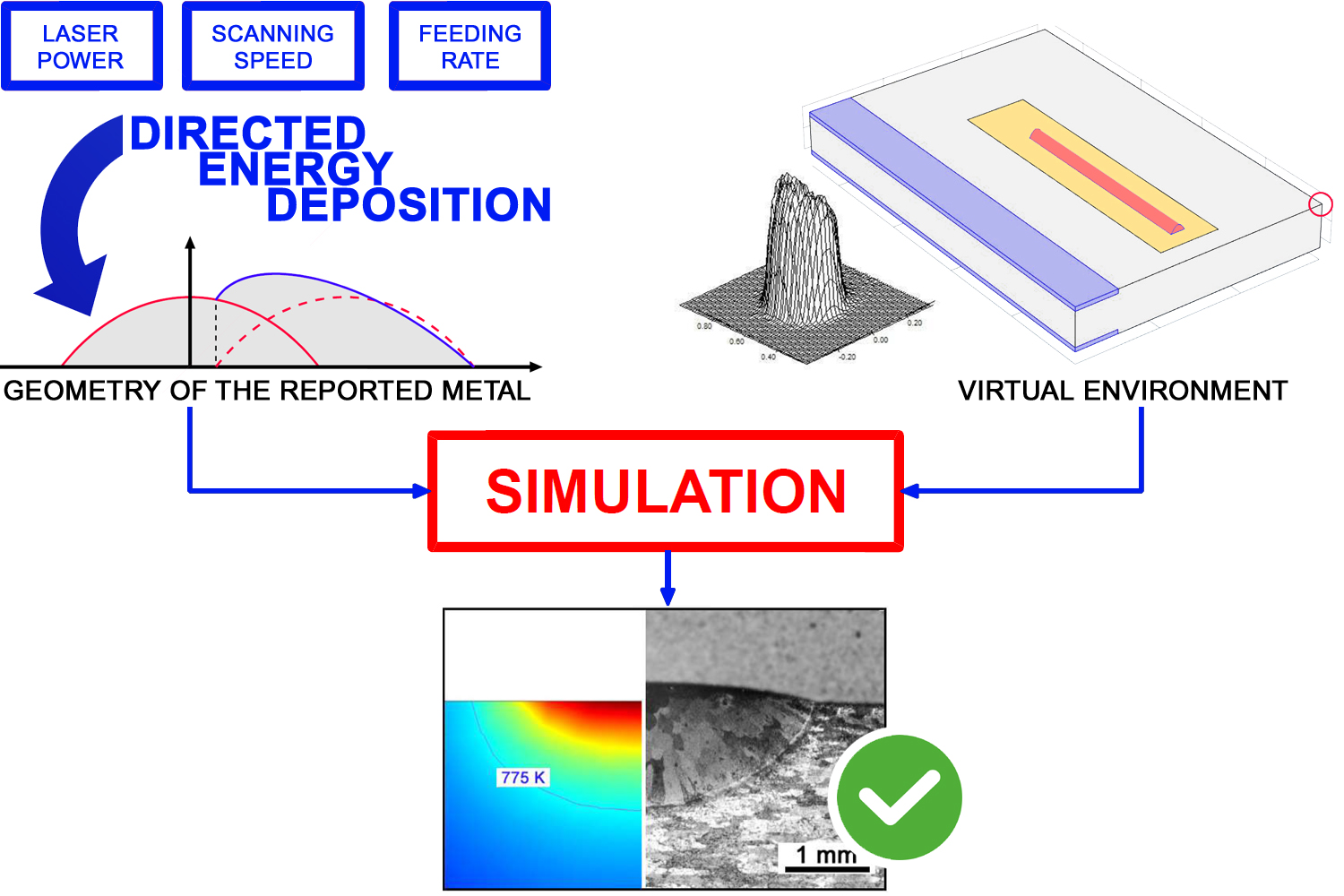

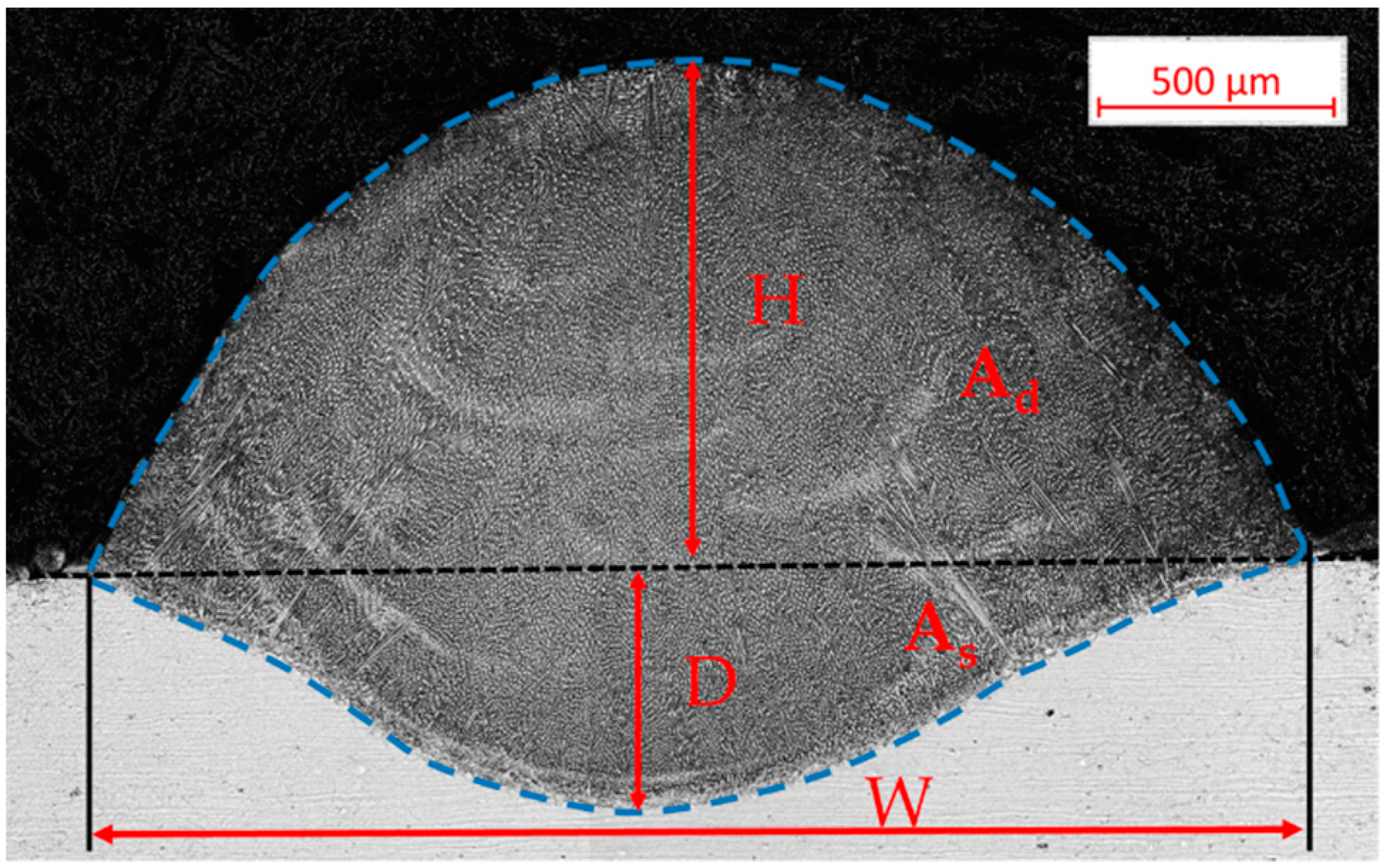

Ded systems use an electric arc plasma laser or electron beam to melt metal feedstock wire or powder into a molten deposit pool.

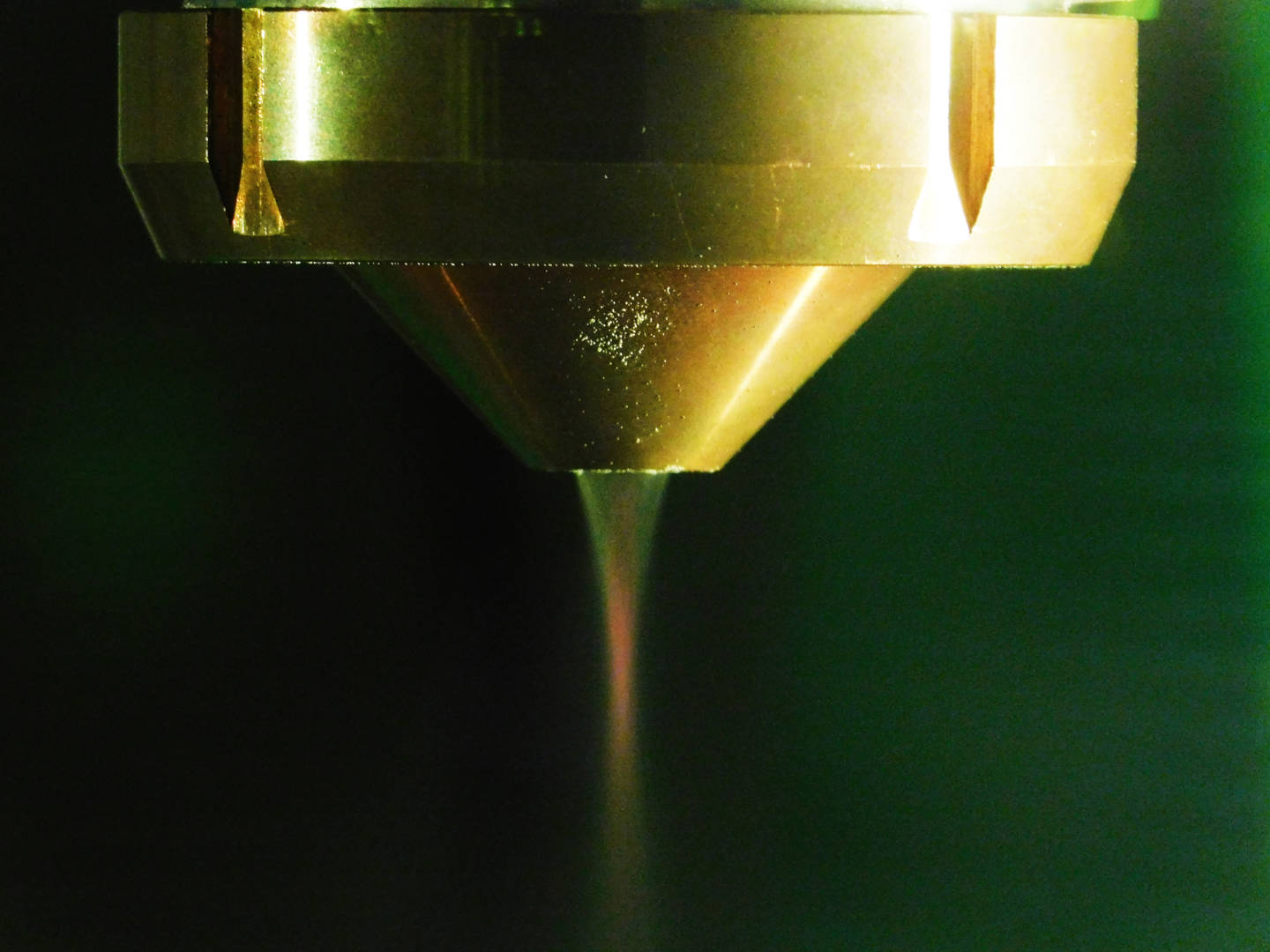

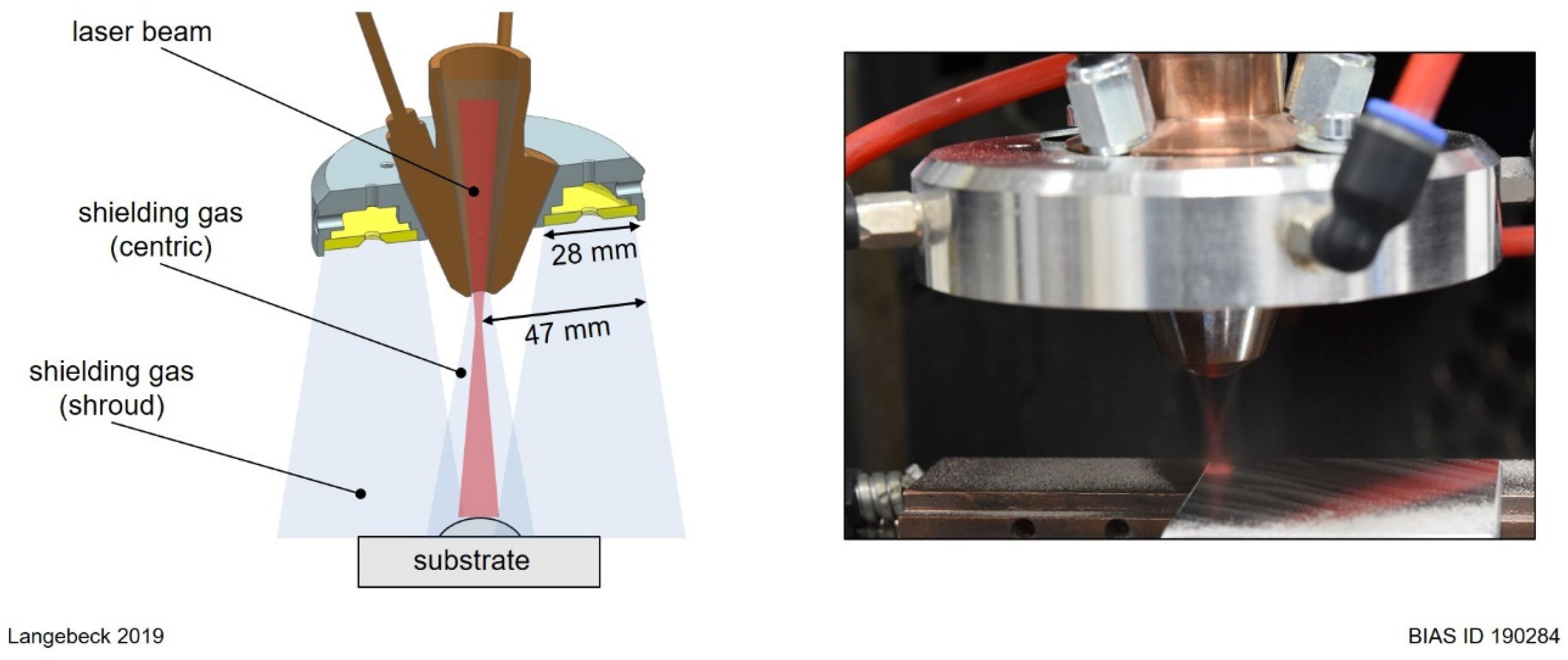

Directed energy deposition of ceramics. These techniques incorporate the characteristics of both power bed fusion and. Directed energy deposition ded powder fed directed energy deposition. In powder fed directed energy deposition a high power laser is used to melt metal powder supplied to the focus of the laser beam. Thus this technology is often referred to as metal deposition technology.

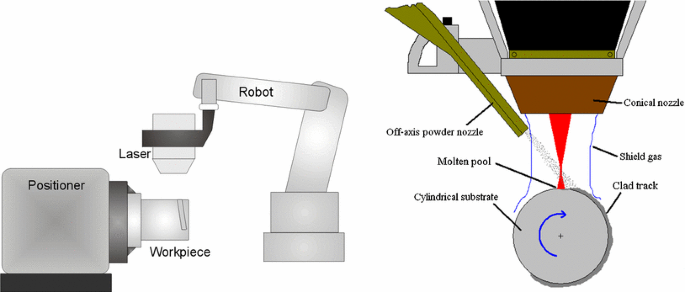

Directed energy deposition ded covers a range of terminology. A typical ded machine consists of a nozzle mounted on a multi axis arm which deposits. This technique is quite commonly used for repair of existing 3d models built using metal or alloy many times the technique is used for adding. The technique can be applied for making 3d parts or objects from polymers glass or ceramics but is not popular for that.

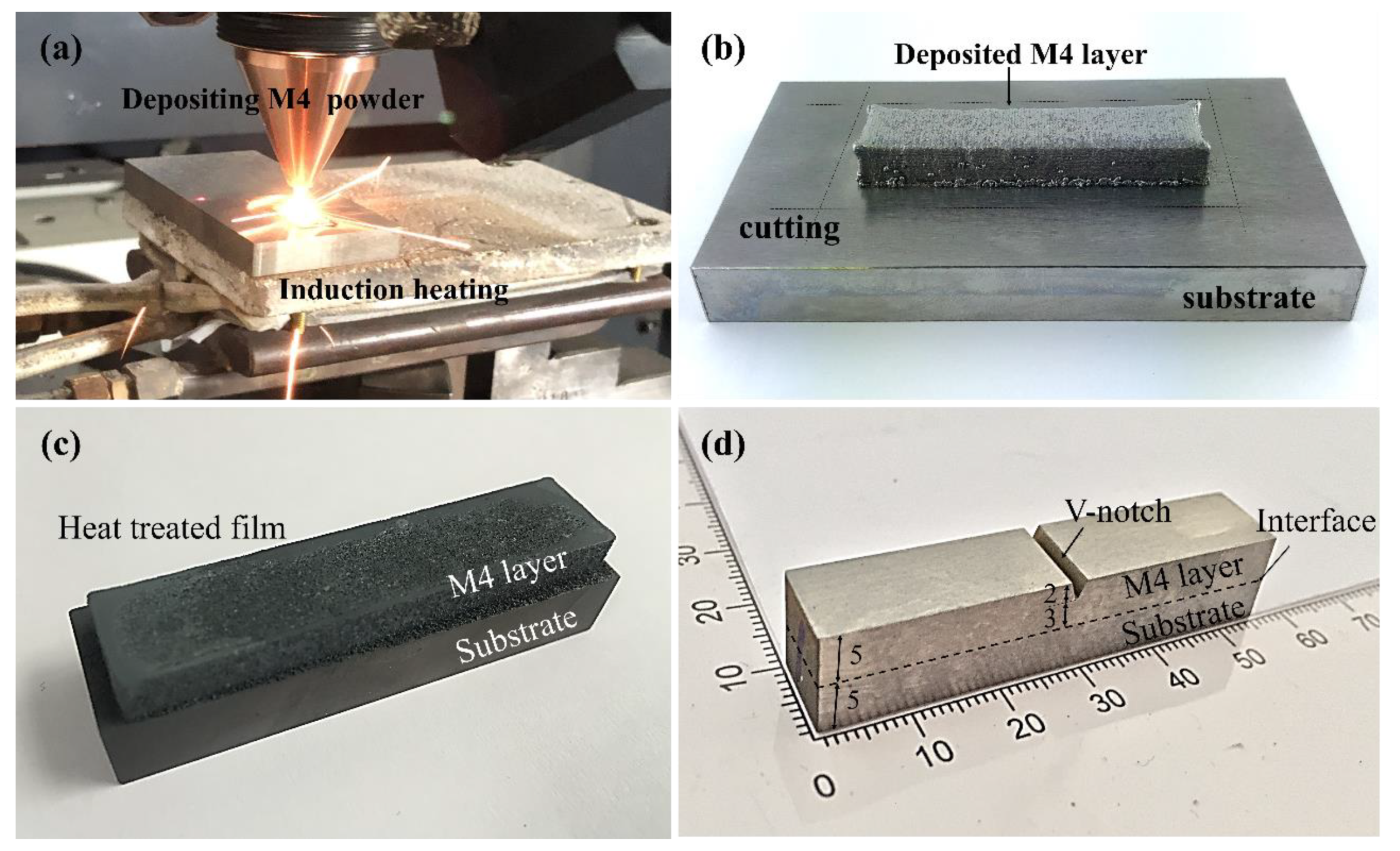

The directed energy deposition ded 3d printing technology also known as direct energy deposition creates parts by directly melting materials and deposing them on the workpiece layer by layer. Directed energy deposition of zirconia toughened alumina ceramic. Directed energy deposition ded processes enable the creation of parts by melting material as it is being deposited. Directed energy deposition generally they all deposit a melted metal powder or wire on a build service.

Directed energy deposition ded is a kind of additive manufacturing am technology based on synchronous powder feeding or wire feeding. Directed energy deposition ded is a 3d printing technology specifically used to create 3d models from metals and alloys. The nozzle that deposits the material is typically mounted on a five axis arm and then. Directed energy deposition ded is a category of metal additive manufacturing am that utilizes robotic welding processes to print at high deposition rates but with relatively low resolution.

Laser engineered net shaping directed light fabrication direct metal deposition 3d laser cladding it is a more complex printing process commonly used to repair or add additional material to existing components gibson et al 2010. Although this basic approach can work for polymers ceramics and metal matrix composites it is predominantly used for metal powders. Novel microstructure formation and mechanical performance yingbin hu yingbin hu department of industrial manufacturing and systems engineering texas tech university lubbock tx 79409.