Direct Laser Engraving Of Rotogravure Cylinder

Direct laser engraving the elastomer sleeves have introduced the concept of seamless flexo printing which means perfect continuity on the repeat.

Direct laser engraving of rotogravure cylinder. This film guides you through the whole production process of a rotogravure cylinder and an embossing roller. If the cylinder is chemically etched a resist in the form of a negative image is transferred to the cylinder before etching. With its numerous technical solutions hell is continuously redefining international standards in its many core areas of expertise the electromechanical and direct laser engraving of gravure and embossing cylinders and the high resolution direct engraving of. Direct laser engraving contactless direct engraving with no tool wear using cellaxy is the optimum method for the high resolution transfer of text linework and intaglio images to gravure forms and of three dimensional structures onto embossing rollers.

The relatively strong laser engraves directly in the cylinder s zinc surface. The desired pattern is achieved by engraving with a laser or a diamond tool or by chemical etching. Hell gravure systems a heliograph holding company is an innovation leader in the manufacture of prepress engraving systems. Unlike the plates the in round engraved sleeves do not have sewing marks in the print.

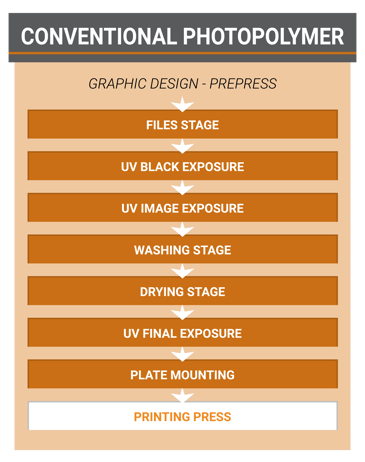

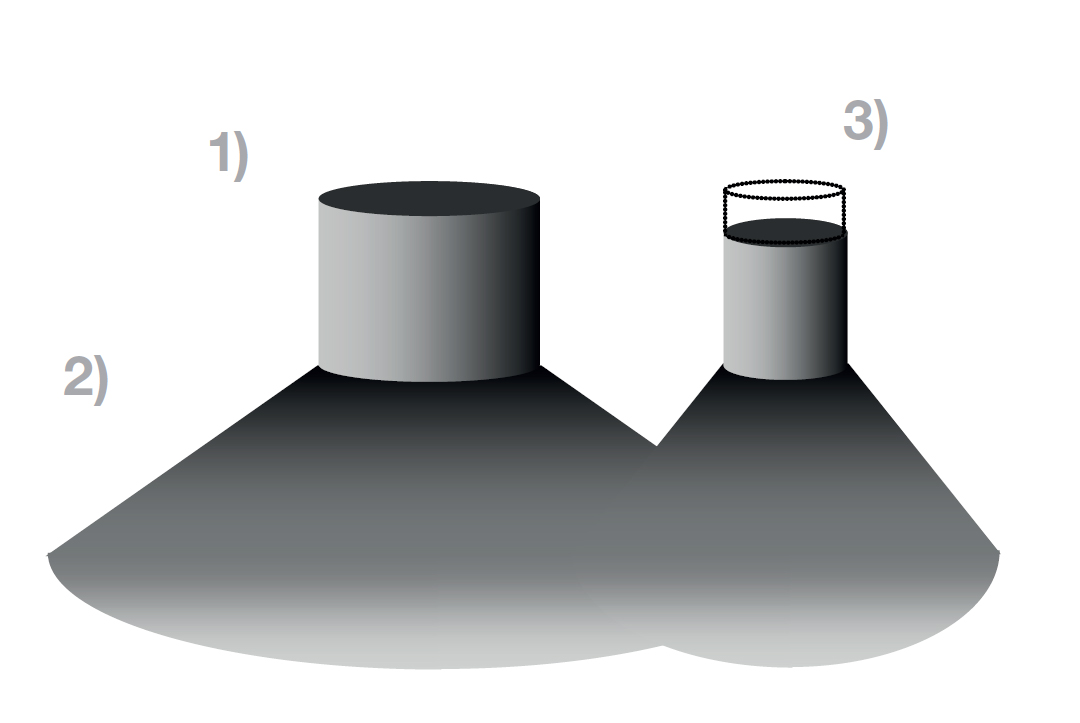

As the substrate is sandwiched between the impression roller and the gravure cylinder the ink is transferred from recessed cells to the substrate by capillary action. The high quality of the daetwyler direct laser systems dls is demonstrated in the image area through high resolution reproduction and outline free vignettes and in line elements through sharp edged text reproduction and excellent evenness of the ink. Like bases preparation methods vary in their ability to address specific printing concerns or desired outcomes as well as the necessities of maintenance down time and other operational aspects unique. Beyond the materials that make up the cylinder another key component of gravure performance is the way cylinders are prepared for engraving.

The resist protects the non image areas of the cylinder from the etchant. After etching the resist is stripped off. For a long time the constraint was the availability of lasers of sufficient intensity and power to directly engrave metallic surfaces at reasonable speeds.