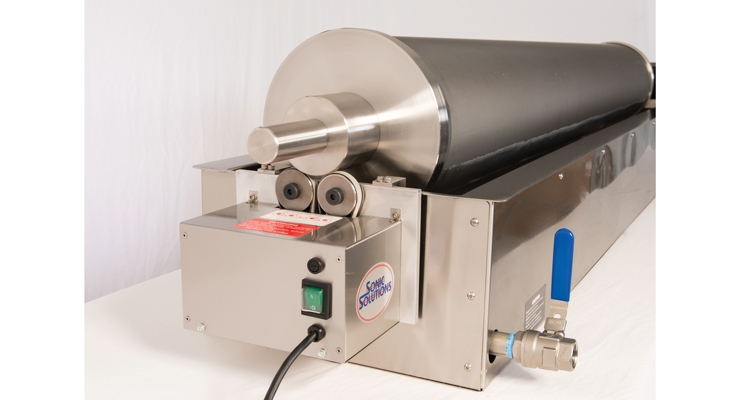

Direct Laser Engraving Of Flexographic Plates And Cylinders

Direct laser engraving of flexographic printing cylinders and plates has been a longtime course of because the 1970s.

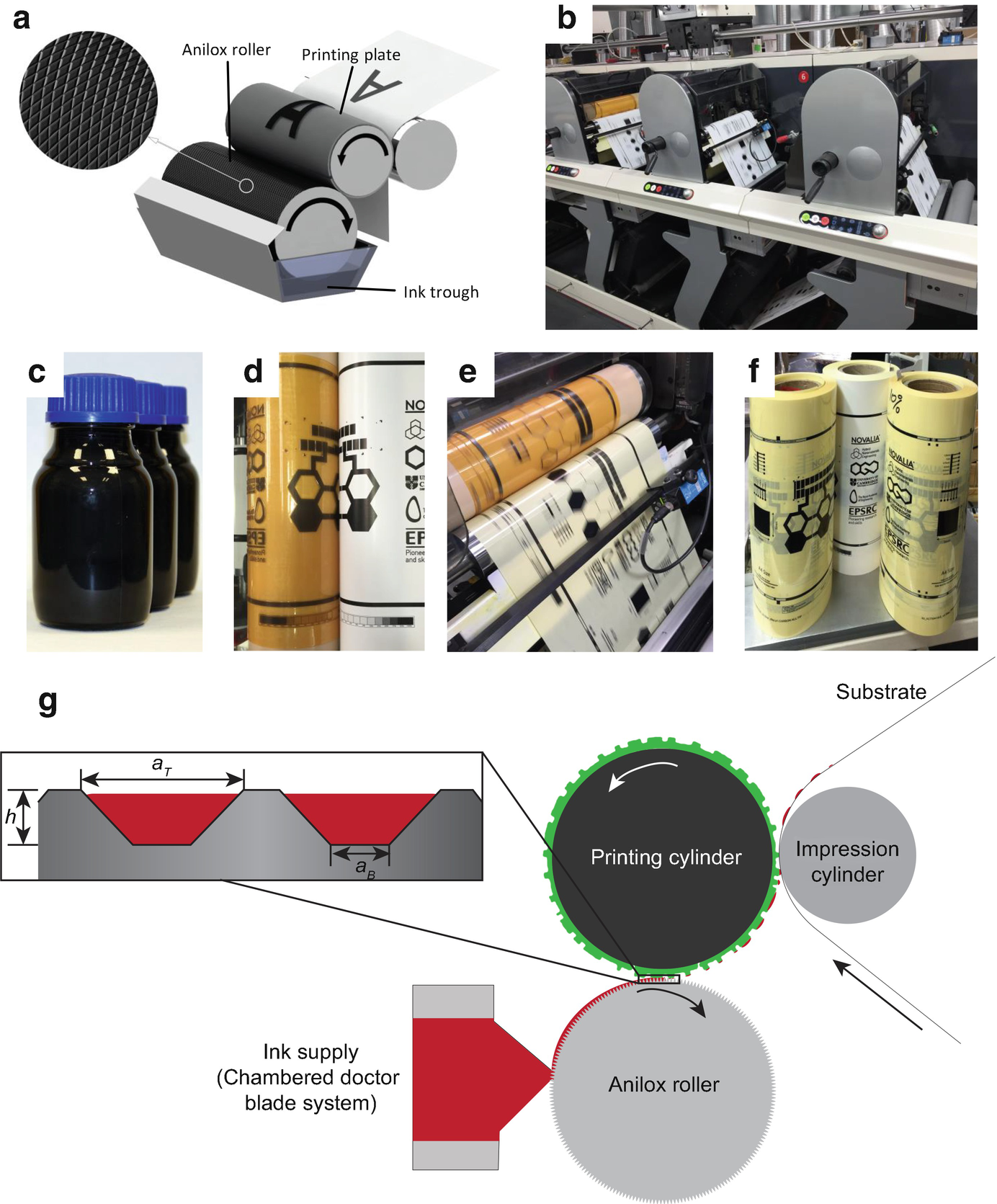

Direct laser engraving of flexographic plates and cylinders. This primary started with using a carbon dioxide laser used to selectively ablate or evaporate a wide range of rubber plate and sleeve supplies to supply a print prepared floor with out using pictures or chemical compounds. The laser selectively ablates the non print area of an elastomer plate or sleeve to produce a print ready surface without the use of exposures or chemicals. This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals. Flexographic engraving systems use single or multiple high powered co 2 lasers or fiber lasers to directly engrave continuous sleeves or plates in a single step.

This eco friendly two stage process offers benefits in terms of quality and cost effectiveness over other methods. Direct laser engraving the elastomer sleeves have introduced the concept of seamless flexo printing which means perfect continuity on the repeat. Reducing printing form production to just two process steps laser engraving and cleaning significantly cuts the workload involved. Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s.

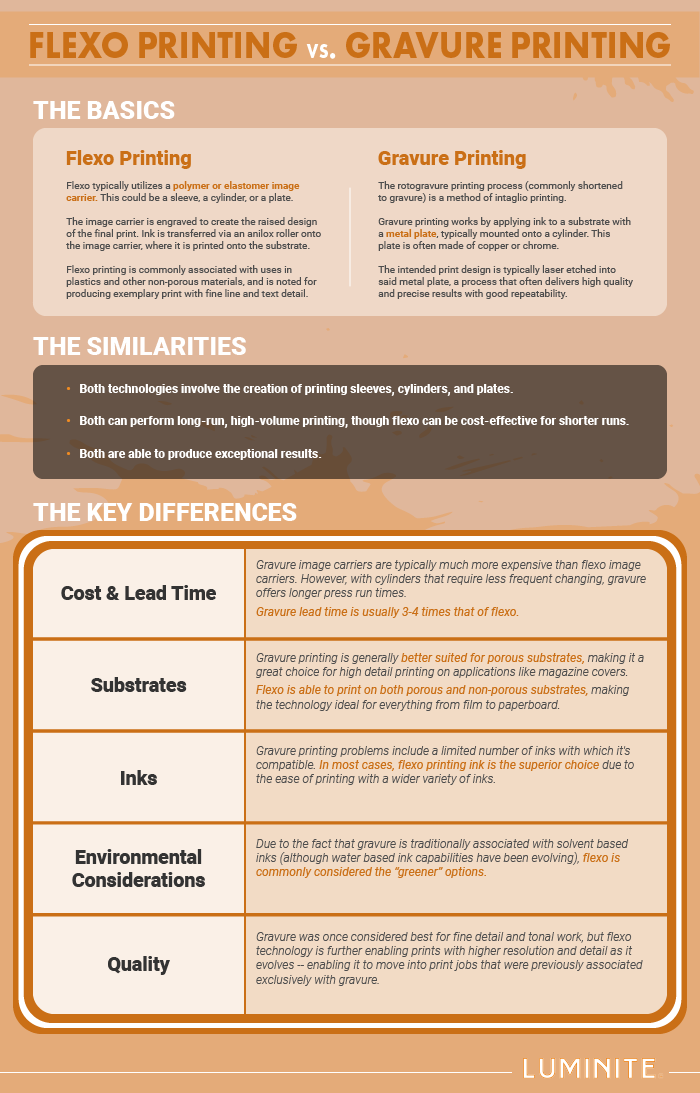

Direct laser engraving of elastomers makes the production of flexographic printing forms an entirely digital process. Providing the highest quality products and services for the flexographic industry since 1926 luminite products corporation offers direct laser engraved elastomer sleeves cylinders plates for the flexographic printing industry. Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s. Laser engraved printing plates can be applied to all flexographic printing processes.

This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals. Unlike the plates the in round engraved sleeves do not have sewing marks in the print. Direct is better as demonstrated to perfection here. Labels flexible packaging films and more.