Direct Laser Engraving Flexo

What is direct laser engraving.

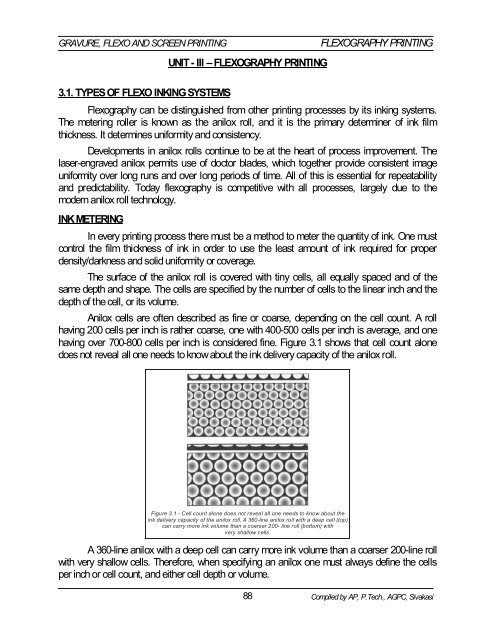

Direct laser engraving flexo. Improve print resolution reduce prepress costs handling. The success of your flexo printing operation hinges upon quality and efficiency. Now with direct laser engraving technology and itr elastomer you can achieve high end print results in a fraction of the time. Direct laser engraving is gaining a stronger position as an accepted alternative to photopolymerisation in the production of flexographic printing forms.

The following is an article written for flexo magazine that explains how dle dramatically improves flexo print quality. Several engraving system manufacturers picked up on these technologies and designed their systems around them. Direct laser engraving in highly productive wide web flexographic printing and narrow web printing with its wide range of surface finishing options is becoming increasingly widespread which proves the market is adopting this impressive technology. The result is higher and repeatable quality reduced manual input and improved sustainability.

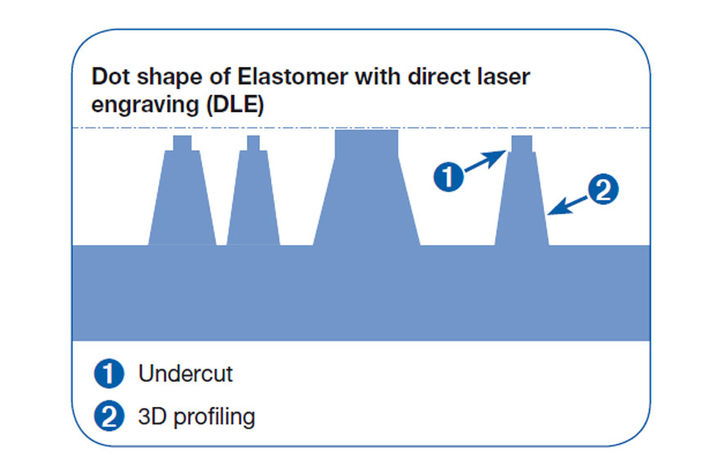

Premiumflexo is the hell technology for razor sharp direct laser engraving of elastomer forms for high quality flexographic printing and elastomer coating embossing forms. Controlling engraving parameters affecting dot shape support. Premiumflexo is the hell technology for razor sharp direct laser engraving of elastomer forms for high quality flexographic printing and elastomer coating embossing forms. Direct laser engraving achieves quality efficiency.

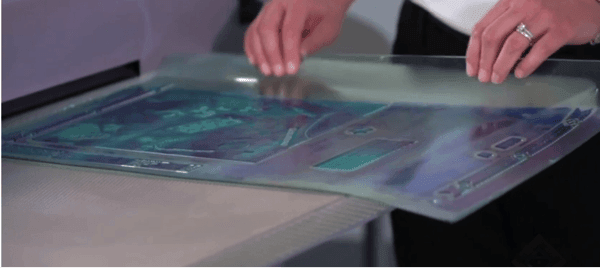

The elastomer sleeves have introduced the concept of seamless flexo printing which means perfect continuity on the repeat. Direct laser engraving of elastomers makes the production of flexographic printing forms an entirely digital process. This eco friendly two stage process offers benefits in terms of quality and cost effectiveness over other methods. Based on both direct laser engraving and ctp technology with accompanying processing software these systems offer a simplified method of imaging flexo rotary screen dry offset and letterpress printing formes.

Unlike the plates the in round engraved sleeves do not have sewing marks in the print. Direct is better as demonstrated to perfection here. This is the process whereby the surface of the sleeve is modelled by means of ablation using a high energy laser beam to create a raised image. Direct laser engraving technology for flexo eliminates the costly outlay for multiple processing stages and equipment commonly associated with more conventional photopolymer sleeve plate making technologies.