Denford Laser Cutter Problems

Router 2600 router 2600 pro.

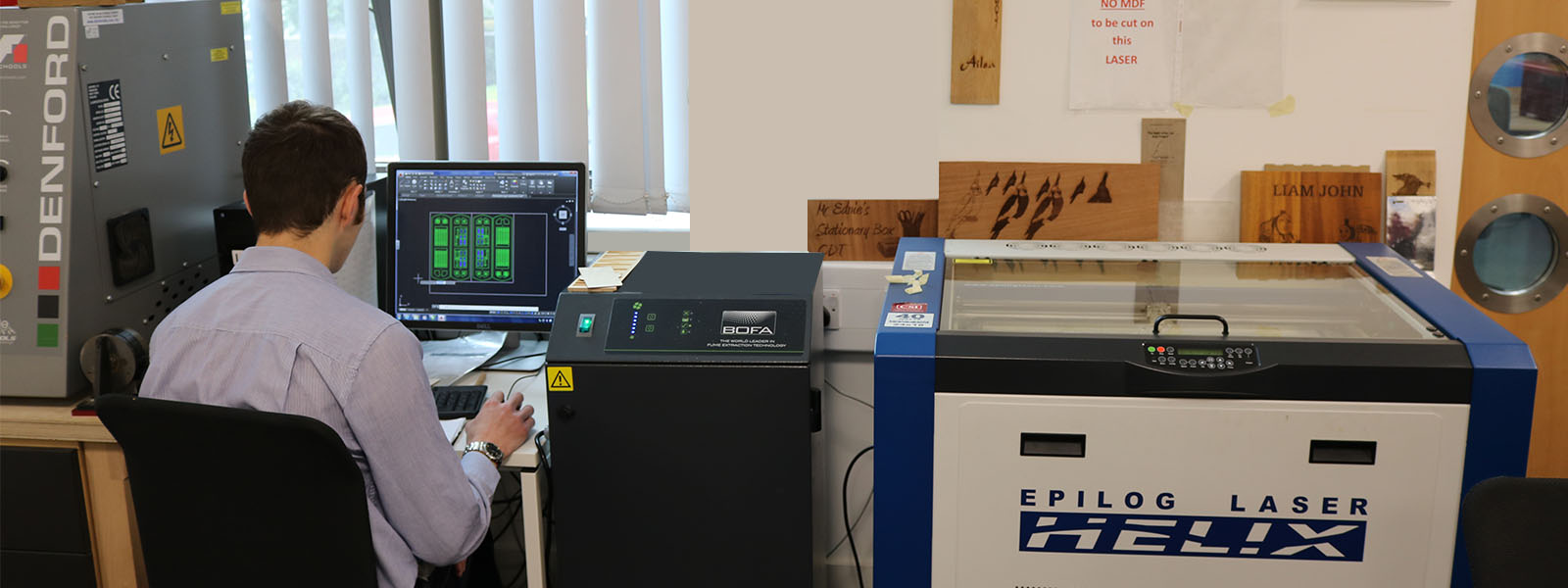

Denford laser cutter problems. Vls series safety features include over temperature sensor with audible alarm safety glass automatic recognition of accessories and smart technology. Router 2600 atc router 6600 atc. Having put up with an unreliable laser cutter for a number of years we decided to go for a universal laser systems vls series laser. Denford usb driver 64 bit 4 mb uploaded 10th july 2019.

Compact 1000 compact 1000 pro. Denford usb machine device driver 13kb nt xp 2000 only uploaded 17th october 2005. The following are suggested laser cutter configuration settings for various materials. Since neoprene polymchloroprene also contains chlorine would i have the same problem.

Won t even cut 2mm mdf at 5mm s and full power. Denford s quote was the most competitive and the staff were very helpful throughout the ordering process. Compressed air up to 4 bar 58 02 psi is used in most laser cutting applications to remove heat and combustible gases from the top material surface. Not sure what s wrong or what i m doing wrong.

I am having problems with cutting through cleanly with my laser my alignment is ok however there are a few more things to check 1 clean the water filter this will make the beam fire intermittingly if algae builds up 2 renew the water flush with tap water and drain then refill with ionised water 3 check the lid sensor this will break the. Denford usb driver 32 bit 3 5 mb uploaded 10th july 2019. I contacted a number of uk suppliers. Also available is a laser cutter user guide.

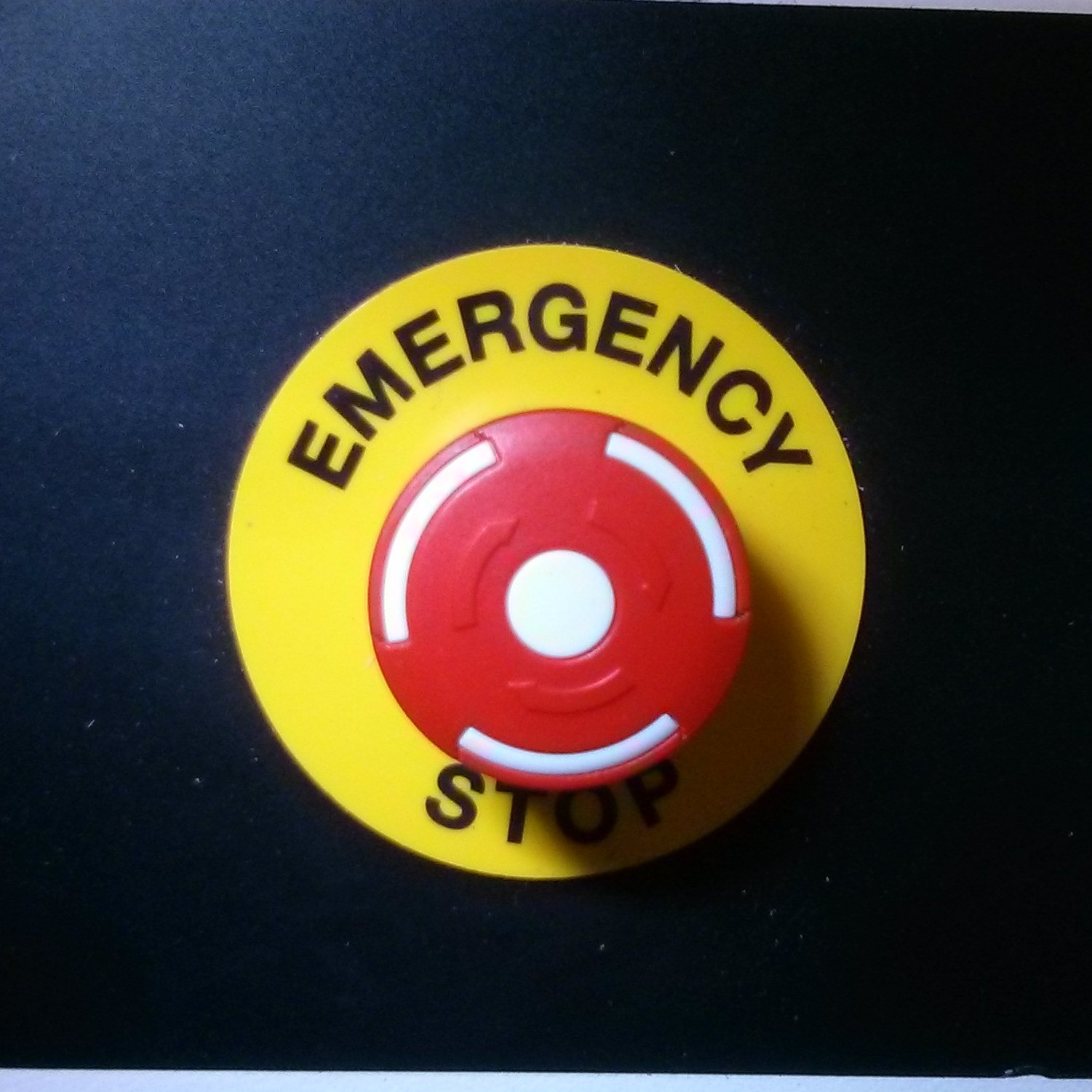

This machine has no power. If you have other settings you d like to suggest please send an email to design help ncsu edu with the details. By directing a constant stream of compressed air at the point where the laser meets the material flaming scorching and charring is reduced on materials such as wood acrylic and rubber.